Krones employs deep learning for empty bottle inspection

Anyone who works with empty bottle inspectors knows that not every canteen that the inspector rejects has a defect. In most cases, it might simply be water droplets or a flake of cream nevertheless clinging to the bottle afterward cleaning. Since conventional systems can't e'er distinguish these from contaminants or damage with 100% certainty, they tend to err on the side of circumspection and reject the container. As a result, countless entirely usable bottles state in the trash in every production shift, never to be seen again.

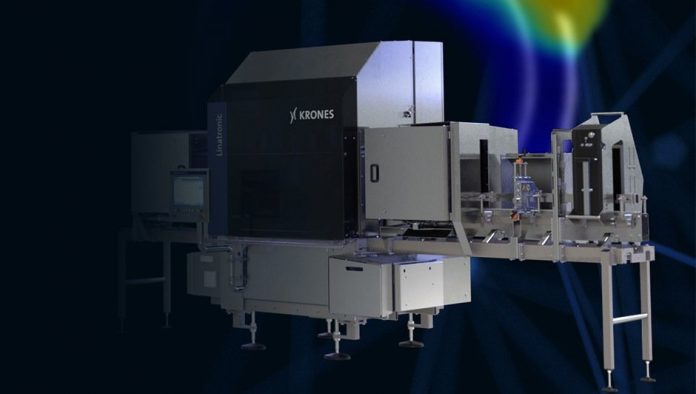

To change that, Krones has taken the evolution of its inspection technology to the next level. According to Krones, the new Linatronic AI employs deep learning software to automatically detect and allocate anomalies, making it much smarter and more efficient than its conventional peers.

Artificial neural networks

Deep learning is a technology that enables machines to do what we humans do naturally — larn from example. Merely there is one big divergence – a car can use this ability many times more than efficiently than humans can.

The foundation for deep learning is an artificial neural network (ANN). The ANN can be described as a complex organisation of multiple consecutive filters. The images captured during the inspection procedure are fed through these filter layers, ane afterward the other. Each layer extracts a different characteristic of the image. Since one filter's output becomes the input for the subsequent filter, the complication of an prototype's characteristics can exist increased almost infinitely. The concatenation ranges from simply identifying night or light pixels to classifying particular objects such as h2o aerosol.

Trained using thousands of images

To ensure that the Linatronic AI applies these filters with the necessary precision in practice, it is trained ahead of time with pre-classified instance images. In this way, its neural network learns to filter out and interpret the relevant image characteristics. The same is true for machines that are true for us humans — the more intensively you train, the better the results. Therefore, the Linatronic AI's neural network was continually fine-tuned using thousands of example images until it could accurately distinguish water droplets from other anomalies – with a reliability rate of over 99.9%.

Every bit a result, the waste product of material due to simulated rejects is no longer an issue. The time-consuming process of configuring the inspector during commissioning is likewise a affair of the past. The neural network doesn't require manual scale to local conditions. Instead, the Linatronic AI is delivered fully trained and ready to starting time piece of work.

Source: https://packagingsouthasia.com/application/krones-4/

0 Response to "Krones employs deep learning for empty bottle inspection"

Post a Comment